Hi all,

I want to use the capacitance / cLLD function to measure the liquid level / height in a microtiter plate (ideally as fast as possible) over time (i.e. every 0.5-1 sec for ~5-10 sec) and extract those values. So far I could only find the ‘Get Last Liquid Level’ function, which would require me to do at least a fake aspirate or dispense beforehand. This causes though extra Z-movement, which takes too much time (I guess that this could be reduced though). In addition, I would ideally use the steel teaching tips instead of the normal conductive tips, as I imagine the capacitance reading would be better (please correct me If I’m wrong) and I could re-use them basically infinitely.

For more context on what I want to do: Basically, I have a 96 well filter plate standing on a vacuum station and I want to measure repeatedly the flow through the membrane filter by measuring the liquid height (for reference this was done apparently already on a Tecan system: https://doi.org/10.1016/j.memsci.2020.118330).

So, is there any way to only detect the liquid level or to set the height of the channel to a specific value and then continuously extract the capacitance recording directly? Does a library/submethod already exist to do something like this?

Thanks a lot for any input and sorry if this is the wrong section of the forum.

Cheers,

Keywan

1 Like

@keyenkay - There are likely custom workarounds to significantly speed up liquid surface detection and prevent spending time returning to traverse height, but I will need a bit of time to explore options. From my interpretation of the scenario, it sounds like there would be more value in faster real-time detection of liquid level (via iterations of surface detection as was described in the linked paper), which could then be converted into estimated remaining volume. cLLD signal alone would not be able to be converted into a volume estimation. Let me know if I am misinterpreting.

I do not believe using needles will provide any advantage over tips in terms of capacitance signal. The conductivity of the liquid and proper grounding of the labware/carrier has always been my understanding of what is key here. I recommend reserving teaching needles for maintenance and verification protocols and avoid exposure to sample material.

Let me look a bit more into this and I can report back with better insight and recommendations.

-Nick

1 Like

While I understand this wasn’t the intent of the original request, in the spirit of public knowledge dissemination over the forum I figured I would also provide example for how to most easily extract liquid level and volume estimation data for standard applications and scenarios - where one would retrieve liquid level and volume data after an aspiration.

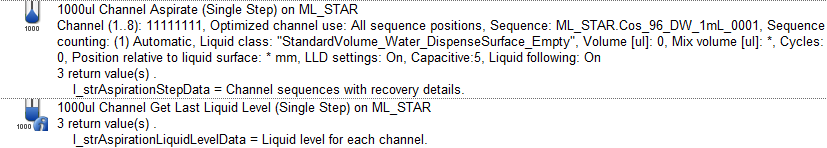

After an channels aspiration step, you will want to call the ‘Get Last Liquid Level’ ML_STAR single step referenced in the original post of the thread. You will want this to be the very next line of VENUS after an aspiration step.

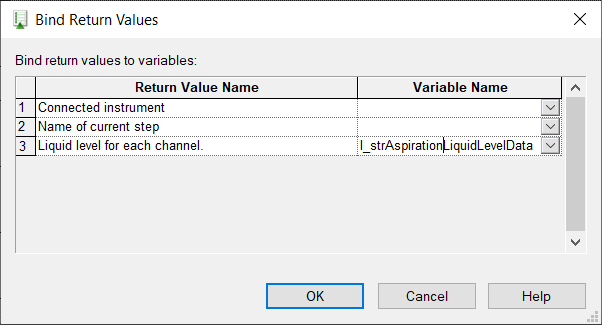

Assign variables to receive the aspiration step data liquid level return data from both steps.

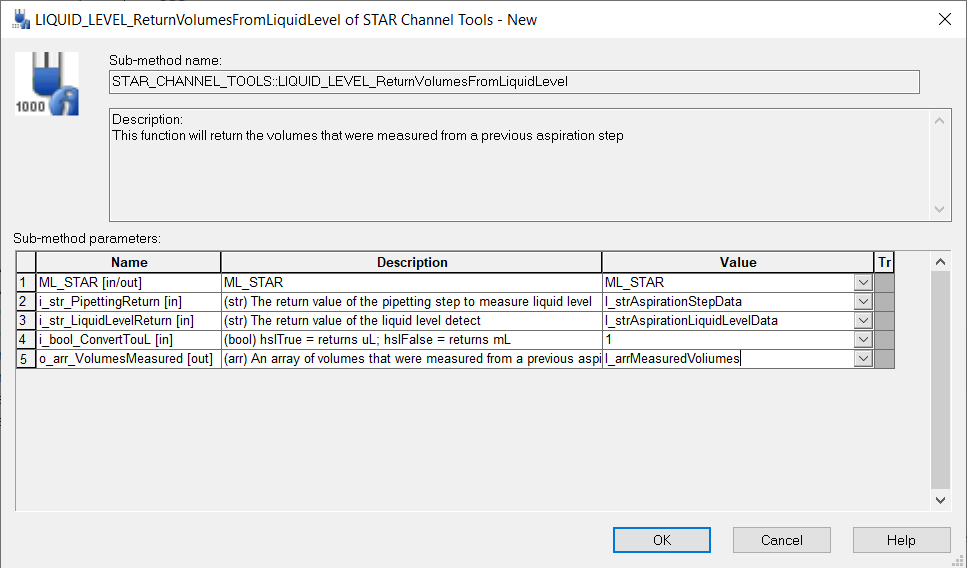

Next use Channel Tools library of the STAR Tools Suite which has been referenced numerous times for various types of applications on the forum.

To receive volume estimations relative to the initial liquid detection from the aspiration step, use the channel tools function ‘LIQUID_LEVEL_ReturnVolumesFromLiquidLevel’, which requires the return data of the aspiration and liquid level steps. This function will parse the step data for liquid levels and convert to volume:

-Nick

10 Likes

You might try scanning with an ultrasonic sensor rather than doing contact liquid level detection - it can be rather faster. The downside is you need to process an RS232 signal to get your data, but it’s pretty fast. Resolution is in the area of 0.1mm in a 96 well micro plate. Baumer makes a nice one.

We’ve used them in rows of 8 combined with an 8 channel dispense head to normalize plates in seconds instead of minutes.

3 Likes

Any chance you could share some info about this solution in another thread? This sounds fascinating. Normalization is so prevalent in the lab automation world this would be great if it were a DIY solution.

I agree with evwolfson. I would be so grateful if Sam would share his ultrasonic liquid level detection workflow

I’d be happy to. I’m tied up for a few days but I’ll try to put something down by th end of the week!

done. Look over in the DIY section and let me know what you think.

1 Like