Oftentimes I find I have “Pressure out of range in x tip”, even when pipetting in labware and my tips aren’t touching anything except liquid. Is there any way to just plain disable this error in fluentcontrol that anyone knows about?

I really just want to ignore this error and “pipette anyway” but that’s not an option with automatic error handling that I can see

2 Likes

First question, is your labware well defined in the software?

Second, are your 8 channels level? I have found that sometimes they are not level so I teach with the channel that is lowest to avoid pinching.

Third, is it one specific liquid class or many?

Fourth, is it beads?

1 Like

Hey Luis!

-

Yeah everything is well defined,

-

The channels are level (they just passed maintenance)

-

It’s a specific liquid class when I go to Z_Max+2. Really doesn’t look like the tips are even remotely touching the botton of the wellplate

-

No beads

I’m really just looking to turn off the error, or at least change the pressure range it comes up with

Asking so future Googlers check those things first!

Also what maintenance step checks that the channels are aligned on a Tecan? I’ve had the FAE’s butcher their Fluent Setup testing so many times.

With that said,

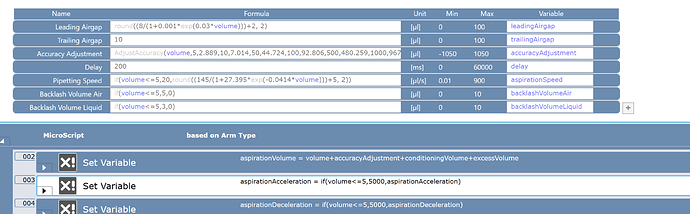

- There are pressure settings you can adjust in the microscript to raise the tolerance (great for any work involving sticky beads)

- Sometimes the default aspirate/dispense speeds are just too damn fast! You can slow these down a bit to minimize pressure errors. You can adjust this in the microscript too.

- You can wrap your pipetting logic in a try - catch block with On Error Go To and then filter the error you want to act on and have the system always auto-select a specific option with On System Prompt. You can then also ask it to report to the error in the log or audit trail so you know what messed up.

I would analyze your microscript of your liquid class since there could be something that you can do at that level without having to change your coding logic

2 Likes

Hey Luis, thanks for your response, really great you’re thinking about future googlers (oh by the way, hello from the past future googlers)

Do you know what those pressure settings are called? I thought they existed too but I can’t seem to find them

Also good idea with the on system prompt message, but the only options with Out of Pressure aren’t quite what I want. There’s no “just do what you were going to do anyway, forget about the pressure” option, from memory they either:

-deactivate the tip,

-dispense the liquid back and do nothing,

-or try again with another tip

Also what maintenance step checks that the channels are aligned on a Tecan? I’ve had the FAE’s butcher their Fluent Setup testing so many times.

EDIT (I forgot to answer): Field Service Technicians have a machined segment with a lot of holes in it that they fix to your machine. They then fix metal tips to your FCA and their software goes through movements to check if your FCA is “in spec” and if your z heights are close enough to each other

I forgot to mention LLD Error Handling Command which gives you a few options including “Liquid Class Defaults”, I’m not sure what that means…

Yes with pressure out of range errors I usually Retry with New Tip but I can see how that’s not an option for some.

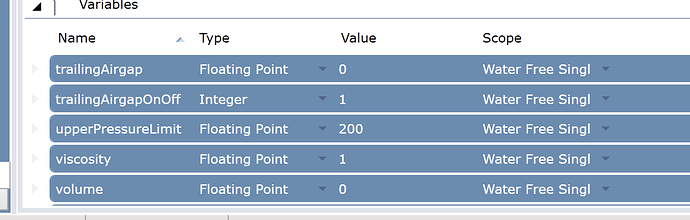

The variables are upperPressureLimit and lowerPressureLimit. You can see what you can control in the Variables tab.

If you change it to 1000, make sure you change the lower limit to -1000.

Also you can set them in the formula or at the top of the microscript

1 Like

With that said, if this is the ONLY liquid class that is acting up… you may want to do a deep dive/follow up to ensure that the pipetting actions are performing as you expect. I’ve seen where a perfectly solid liquid class started to fail because the original engineers weren’t thorough at all with how the tip behaved so while we could modify pressure variables, it ended up hiding the problem at the cost of cretaing hardware errors.

1 Like

Thanks for the detailed response Luis

The variables are upperPressureLimit and lowerPressureLimit. You can see what you can control in the Variables tab.

Do you know what the units for pressure limits are? It seems to want me to input a unit when adding it into the formula tab

Otherwise I’ll just throw it into the microscript tab

With that said, if this is the ONLY liquid class that is acting up…

That’s a good point, but I cannot for the life of me figure it out, because it seems fairly random when it shows up. I’ll keep investigating but changing the pressure limits seems to be a good bandaid fix!

I would set it at the microscript level for now and see if that makes a difference.

Hail Mary option (and this is the convo nobody likes) you could create a fresh version of that liquid class with the exact same parameters and data. I don’t know your system history but in the past I’ve had problems with liquid classes and labware made in older versions of Fluent Control being used on newer versions of the software.

At some point I decided to not only standardize the labware across methods and workflows but also recreate it in the most current versions of the software we were using in the lab. The downside to being one of the earliest adopters I suppose.

1 Like

As another note, I’ve seen POOR (pressure out of range) errors on LCs that mix if there isn’t enough delay between asp/disp or if the mix occurs too close to Z_max with higher mixing speeds - typically in channels 1,2 or 7,8 on a LiHa. The Fluent is sometimes too smart for it’s own good.

In these cases, up the delay time momentarily to allow turbulence time to settle, or apply a pattern like aspirate near Z_max and disp near Z_liquid or vice versa. I’d personally avoid extending the pressure ranges if the POOR error isn’t the direct result of clotting or pinning of the tips. And one last thought: possibly replace the inline filters just in case.

2 Likes

Totally, would advise against modifying the pressure generally but if you need the system running while investigating… it’s an option.

1 Like

Ah thank you @evwolfson ! I am indeed mixing here, I’ll put in some days, give it a shot and report back

Is the error step is a mixing step, for sure slow down the speeds. The speeds for the default mix values are too fast.

Hey @luisvillaautomata Luis

No it’s not an actual “mix” command, since it’s a worklist where I need to use the same tip to mix / transfer / mix again, I just have mixing within the single liquid class I assign the worklist.

The lowerPressureLimit and upperPressureLimit did the trick. I noticed in their default water_mix command they actually even change it to -1000 and 1000 respectively.

Also @evwolfson I put in delays as well, that might have also fixed it, I didn’t test them individually

Thank you both for your help!

1 Like

Hey everyone,

I have come across the ‘Pressure out of Range’ error a few times as well and this happened a few times when working with the Ampure XP beads. I thought about changing the following but am unclear about what settings would be best.

- changing the min / max pressure settings (if someone has a settings that works that would be great)

- Adding a delay during the aspirate / dispense

- changing the level of z-max (add a + 2 as suggested above).

Don’t know which ones would be best to try first though. Does anyone know if there is a place to get ‘template Liquid classes’ for specific liquids types? At that way I can find out what would be considered as standard for that specific liquid and then get going from there.

Thanks for your imput,

Dirk

Amsterdam

Hey there Dirk Amsterdam

Does anyone know if there is a place to get ‘template Liquid classes’ for specific liquids types? At that way I can find out what would be considered as standard for that specific liquid and then get going from there.

Typically one just copies and modifies a liquid class that pre-exists in fluentcontrol and works off of that, pick the one that’s closest to your liquid for that step (there’s a way to have the machine detect your liquid’s conductivity in the machine, I think it’s a direct command)

- changing the min / max pressure settings (if someone has a settings that works that would be great)

- Adding a delay during the aspirate / dispense

- changing the level of z-max (add a + 2 as suggested above).

I’d really do all of the things you suggested. If you don’t particularly care about exact volumes and just want the machine to not throw an error, I’d change the min / max values to -1000 to 1000 (if you’re absolutely sure you’re not hitting somewhere within the well that is)

I used to run into Pressure out of range (POOR) errors frequently with AMPure beads when mixing in a 100mL or 25mL trough - typically on channels 1,2, 7,8 so I assume it has something to do with liquid properties near the edge of the trough.

Expanding detection limit rarely solved the POOR error outright so likely there’s a massive spike in the reading rather than just a minimal outlier. What helped was slowing speeds, increasing delays, and playing with the heights to ensure enough space for the liquid jet to disperse without creating significant pressure that triggers POOR.

Similarly, the Tecan channels seem to make a ultra-precision-jet like spray pattern and aren’t that effective at mixing when close to well bottom. If this is the environment that your own problem is happening in, decreasing well depth at mix would likely help both efficiency and error issues.

Also, Tecan doesn’t mess with liquid type validation so you’re unlikely to find any AMPure specific LC. Refer to the Hamilton LC manual and look at some recommendations for med-high viscosity fluids

I’ve seen similar issues with AMPURE beads,

what I found is best is to operate multiple mix cycles, with cyclical increasing of aspiration/dispense speeds with large delays and large volume,

starting with a slow aspiration/dispense e.g. 25 uL/s with large 2-3 second delay - this initial mix starts the pellet breakdown with large % of available well volume e.g. 750 uL

the “next” mix is maybe 50 % faster - to further breakdown the pellet

next mix is faster again

sometimes the above isn’t enough and you still see POOR errors - this could warrant a change to a wider bore tip

happy to go into more detail if you want to DM me

1 Like

Thanks for all the feedback. I’ve implemented the three settings slightly and the first couple of runs went without any hitch.

1 Like

Thanks all for the useful information.

I can add some of my experience: pipetting liquid (methanol) from on top of agar medium.

With a submerged depth, especially when the detection (clld) ended up in a bit deeper than it actually is, the chance of tip hitting solid agar is quite high. The touch of agar will block aspiration, thus causing “Pressure out of range” error.

Changing upper- and lowerPressureLimit to ±1000 in methanol liquid class solved my problem. When the tip is blocked, negative pressure will build in. When retracting, it will suck the rest, although not all, because it goes too fast, of the liquid in.

Fits my needs: as much as possible, but no need to be accurate.

There are limits for these values, I tried ±1500, report error, so I guess ±1000 is their limit. Not sure if ±1000 actually means to let the machine aspirate anyway.

1 Like