Hi all! Our team has been having some issues with extreme drifting/zeroing issues our Mettler Toledo WXS205SDU Balance that we wanted to use for volume verification on both Tecan Freedom Evo Platforms and Hamilton Vantage platforms that we have.

We bought the Liquid verification Kit (LVK) from Hamilton, which includes the Balance, a temperature/humidity reader, a display, LVK software, Hamilton carriers, weigh pans for various tube adapters, as well as a weigh pan to fit SBS plates. We then bought the integration kit from Tecan, which includes Tecan specific carriers.

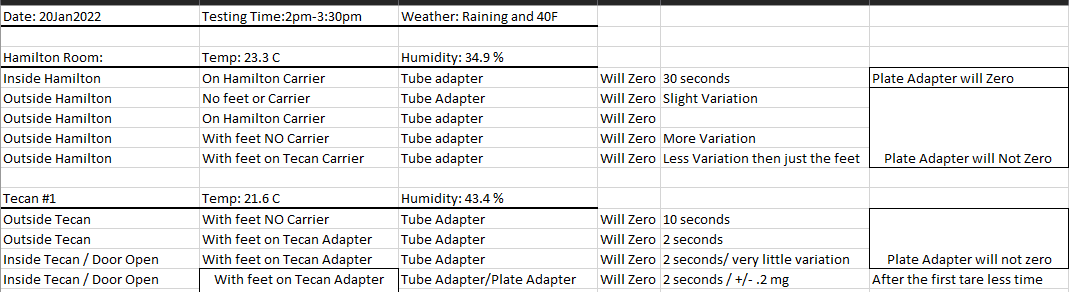

After figuring out how to change communication settings (not straightforward; Tecan really needs to update their manual from 2007), we are able to successfully communicate between the Mettler Balance and both the Hamilton Vantage and the Tecan Freedom Evo. We can successfully use the tube weigh pan with no issue on both platforms; the mass stabilizes and allows zeroing after a minute or so.

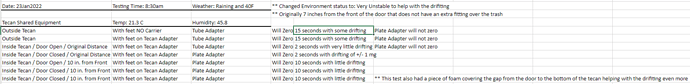

The big issue we have now is with the SBS plate weigh pan. On the Hamilton Vantage, we have no issue with the mass drifting (maybe ±0.2-05 mg); although oddly enough we get less drift when do not use the acrylic cage/cover that is also provided in the kit to prevent air disruption. On the Tecan Freedom Evo platforms, the SBS plate weigh pan takes hours to stabilize. The mass will start off drifting (in either the positive or negative direction) ~1 mg/sec, eventually slowing and stopping after 1-2 hours. This long amount of time to settle makes testing volumes with the MCA96 head not practical.

To make this even more confusing, we happened to have Hamilton in to do a PM while we were having this issue. We hypothesized that perhaps there was something wrong the SBS plate weigh pan. We took the Service Engineer’s SBS plate weigh pan, and put it on our LVK scale while it was connected, and had no drift issues. However, we then had no issues when we put our SBS plate weigh pan on the scale. Fast Forward a few weeks, and the issue has returned. All of this is with the acrylic cage/cover on it that should theoretically stop air disruption.

Other notes about the environment:

We have Two Tecan Freedom Evos, each on separate floors, but in large lab spaces. Both have enclosures, although one has a larger hole in the locking door than the other. Blocking off the hole in front of the door with a lab diaper seems to help. The scale sits 7 inches front of the instrument on its Tecan carrier.

The Hamilton Vantage is in a small enclosed room, where the air flow is noticeably more stagnant. The scale sits 10 inches back form the front of the Hamilton on its carrier.

Has anyone else ever seen this issue? Does anyone successfully use the SBS plate adapter on the LVK kit on a Tecan platform? Thanks everyone for being so helpful, this forum has become a daily read for me!