Hi there,

I’m not sure if this is the right subforum so please feel free to move this topic if it’s not.

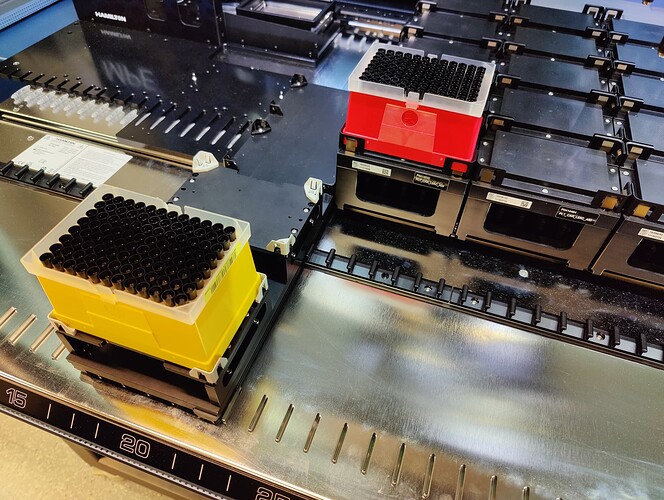

I’m planing on using the new hamilton tip boxes as shown in the picture:

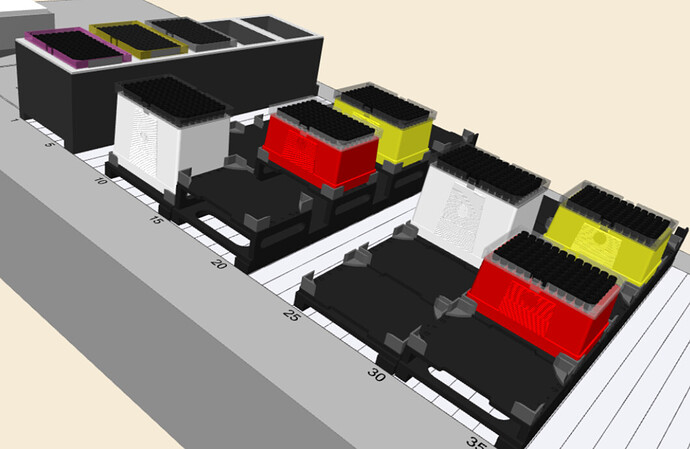

The problem is: They cannot be placed on a deepwell carrier since this violates the traverse height. So I think I have to place them on a multiflex carrier which only has 4 positions im my case. So am I right in the asumption that if I wanted to use 4 (or 5) of those boxes (either 300 or 1000 uL) I’d need 2 multiflex carriers, one with medium height segments, and one with low segments for the 1000 uL boxes?

Is there such a carrier with 5 positions? I’d prefer not to waste the space.

Or is there a better workaround for my problem?

best

Dominik

@dominik.b - Due to atypical labware transportation considerations unique to the tip boxes, extra space is required between each tip box labware carrier site, which is why they don’t nest as densely as normal.

Regarding heights, generally speaking it is best practice to have the top of all labware on deck be flush/aligned at the same z height. When the top of a needed rack is lower that adjacent labware, you could have access or collision considerations when using the MPH, IPG or track gripper to access the labware. Again, this isn’t required in 100% of situations, but this is one of the primary reasons why carrier and MFX module heights vary, as they are tailored to their compatible/intended labware at consistent height.

For the tip boxes, you will want them all at the same height if using the IPG for transport or if using the MPH for the shorter height boxes (50 and 300), which is why those MFX sites contain appropriately sized risers. The 1mL boxes are so tall that they reside directly on a plate locator (fixed directly to the carrier base) without the need for risers.

If it weren’t for the need to transport these tip boxes, they could nest at 5 per carrier, but if that were the case you would want to use standard wafers and tip carriers.

-Nick

1 Like

Hi Nick,

thanks for the quick reply. I talked to my sales rep and he offered me a carrier with 5 racks as I don’t need to transport them but still want to have physically separated tips per plate which I can reuse without the risk of cross-contamination. Now I’ll have one carrier for the 1000 uL boxes (which will carry 4 boxes) and one for the 50/300 uL boxes (which will carry up to five).

2 Likes

Ah ok that makes sense and simplifies things.

-Nick

Could we get the tip box labware definitions uploaded to the file repository?

I saw the 4-spot carrier for the 1mL tips but nothing for the boxes themselves. Does a snappable definition exist or is it just something I should make up ad-hoc if I need it?

They have been uploaded here!

4 Likes

Please let me know if anyone have any specific questions, as we are using the 5 carrier position for low profile, mid profile. Also @mnewsom : we have all of there defiantions

1 Like

So, the Carriers arrived, still I’m missing the definition. Are there official templates for these including those neat 3d models or shall I just use the 1 mL and 50/300 uL base and adjust / teach them according to my needs?

best

Dominik

@dominik.b there are proper labware definations for these. @EricSindelar_Hamilton : cna u pass some if not i can try to upload

Thanks, Kalpesh,

I already fixed / teached it myself

Sorry, all. I thought what I posted included all the definitions, but I see that they’re only the 4 position ones (which are needed if you are doing any transports). Let me follow up and collect the 5 position ones.

Curious… Why is it best practice to have the top of all labware at the same z height?

If a rack is seated on deck in a manner that allows the top of neighboring racks to sit a higher Z (ex. MTP on a DWP carrier next to a DWP on a DWP carrier) then you can have potential access/collision considerations when moving the lower plate with a gripper or arm. When attempting to pick up the lower plate, the wrist, elbow or shoulder of the gripper may come into contact with the top of a taller neighboring plate when approaching the shorter plate. If the top surfaces of the neighboring plates are flush to the same Z, then this is of no concern.

Similar considerations apply if using the MPH for shifted pipetting of partial racks (rows or columns), or if using the MPH to access a rack at very low Z, where there may be other labware at higher Z behind the rack the MPH is attempting to access.

Finally, non-uniform Z heights of plates may also result in autoload scanning issues (for STAR) if plate barcodes are in unexpected locations. Of course, this in not an issues if using a Cognex scanner.

The above considerations are not required in all situations, but ensuring uniform labware top Z height is the best way to future proof your deck as method requirements evolve over time, and avoid unnecessary hurdles when developing your method.

-Nick

2 Likes

Apologies for the delay but tip box definitions for 4 and 5 position carriers have been posted here. Updated 3D models included!

2 Likes

Are you allowed to share the .stl or .step file so I can 3D print these boxes?

I’m sorry, but it is against our policy to share such files externally.

It was worth a try! Thanks

Hi Eric,

When using these labware definitions, the lids don’t actually “link” to the top of the tip boxes as expected. They “link” to the carrier itself, do you have any remedies for this to link to the top of the tip box instead?