@dominik.b - Yes, TADM can and has been used for such instances (phase separation, sample rescue prior to clogs etc.), and IMO really showcases the capability of our channels when leveraged appropriately. Depending on the application though, there can be some nuance involved, and would need some tailoring and customization per the specific aspects and requirements of the particular sample transfer, and a forum post may not be the best venue for attempting to capture that level of detail and information for a full implementation.

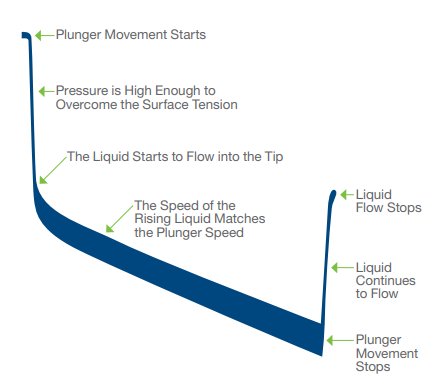

For more background on TADM monitored transfers, I highly recommend checking out section 7.2 of the Liquid Handling Reference Guide linked in Eric’s shared materials folder, found in this post. Here are the cliffnotes there for the working principle:

-

Internal pipette pressure sensors monitor and capture real-time pressure data during aspiration and dispense (ex aspiration):

-

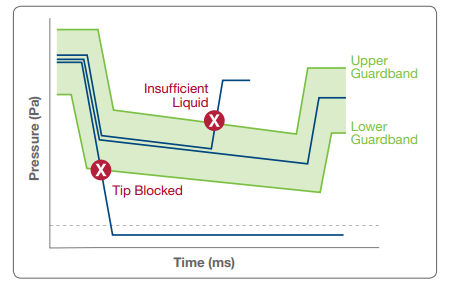

For defined transfers of a consistent volume, the liquid editor can be used to define upper and lower gaurdbands that define the allowable pressure values for a given routine transfer:

-

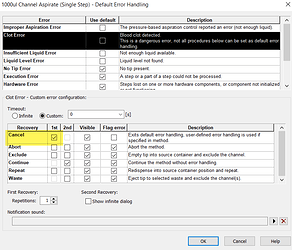

At run time, if there is a clog, during an aspiration, it will immediately trigger a significant underpressure, where the pressure curve will drop out below the allowable bottom threshold. When TADM monitoring is enabled in system configuration, this will trigger a clot error, which can be configured for custom error handling code to handle the clogs.

-

One would then parse the step data of the aspiration to see which channels/samples were affected, which is another topic entirely.

This is a pretty advanced technique, and for a new user I would highly encourage reaching out to your local applications team for support if this is your only option for this transfer. We can also put you in touch if you would like to be pointed in the right direction.

Given the relative complexity and custom nature of the above approach though, I typically only recommend it if this is your only option.

All that said, depending on your scenario it may not be required to accomplish your transfer, and there may be simpler means. Are the pellets consistent in size and surface? Would the pellet be less prone to prematurely generating a clog if you lowered the aspiration plunger speed? What is the reasoning for the 20s wait time in between aspirations?

-Nick