Hi Luis, I’m curious if you did end up posting a reply on GitHub or somewhere on this forum?

I’m interested in info on passing variables into liquid classes in general. Thanks!

We did cover passing variables into a microscript elsewhere in this thread - Fluent Control Wishlist - #15 by MortenSkovsted

This is how we pass info to arrays from a VB.NET script - Fluent Control: Accessing Data in Arrays with VBs?

Does that help? I think @evwolfson compiled thread elsewhere but I could not immediately find them

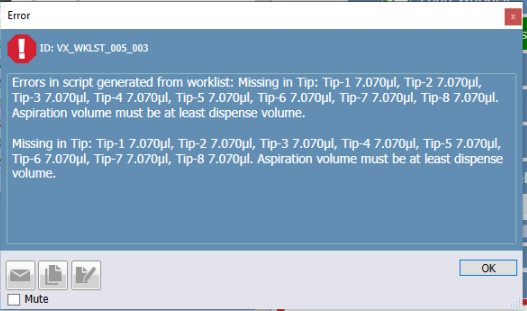

I tend to post them as I get fed up with them: Hope I’m not spamming this thread ![]()

- Worklists should tell you what lines they failed at, that would be super nice

This would be an okay error message if it mentioned what lines it was unhappy about. I know you know FC! Stop being coy!

EDIT: This is FC version 3.0.16

It would be great if this was done for loops and logic in pre-validation as well.

I wonder if there’s a way to add comments to worklists that you could parse in the audit trail or logs to achieve a similar goal?

@Shinedalgarno what version are you on?

This could be anecdotal but I’ve noticed some better error logging on FC3.4 SP1. I don’t know when they modified it but you can also get more precise error data when creating a method with subroutines. Previously it was just a generic error message.

I’m so glad you posted. I’ve been using the import/export method for months now, completely unaware.

My wishlist for FluentControl:

- Text based scripting language. A visual programming is easy and all, but I’ve learned to program now. So having a native programming language with it would be great for me. I’m tired of clicking down arrows when trying to debug or simplify complex scripts, or going through 30 if/else statements.

- Setting scope for variables within liquid class microscripts. Won’t need funky workarounds then.

- Updated X3D mesh format or specifications. When I reached out to them they told me the only software that can make them is no longer available. The company that made it no longer exists and I can’t find the software anywhere.

- Scripts that can run without a worktable. I have some utility scripts that I’d like to use across various methods, but I need to remake them for each one because they use different worktables.

Hi @avargas, I’d be happy to help address item 3 on your list. It is very much possible to create new mesh files in the x3d format. Is there anything you are looking for in particular? If it’s a device, we may already have a definition created that we could share with you. If you are trying to make custom parts and would like to be able to create your own mesh files, I should be able to help there as well.

This is awesome! I’d love to learn more.

Hi Luis, I start by creating a simplified version (remove screws/screw holes, unnecessary details, etc.) of the device/labware/carrier in CAD (I use Fusion 360, but any CAD software should work just fine). There are a few tricks here to ensure things show up properly when loaded into FluentControl.

First, the proper orientation of the part in your CAD software is such that the “Front” should actually be the bottom, and the “Top” should be the front. Next would be dealing with assemblies - FluentControl seems to hold onto different orientations for different parts of assemblies, so even if they show up nicely in your STEP file or even x3d, FluentControl will revert it back to another orientation, causing the mesh file to show different bodies in different orientations.

Once you have created a simplified version of your CAD model, you can export it (I typically export as STEP or IGES), and then convert to x3d. I use CAD Exchanger, though there are other options out there. I just tried imagetostl.com, and that worked, though it did lose the color data. It also looks like some CAD software packages allow for a direct export to x3d.

This is incredibly useful, thank you!

Thanks Eric. This is really helpful. I sometimes make custom applications with equipment that isn’t built for automation, so there wouldn’t be meshes already available.

It was more for a pet project that I wanted to see a proper mesh for. I’ll definitely try this out.