Hi all,

I’m programming a bead extraction on our machine atm, and have an issue with droplet formation on the tips of the MPH. I use the new tips in boxes and for those not to clog after being in contact with a high-salt buffer, I wash them with water. For this washing step, I have one DWP per tip box, where I perform a 0 volume aspirate with 3 mixing cycles. After the mixing in the water, there is NO droplet on the tip, but I think there is a little bit of residual water in the tip.

After the mixing I put the tips back in the tip box until I need them again. When the tips are picked up for the 2nd time (or any further time) I think the pressure of picking up the tips pushes the residual liquid out of the tip, leading to droplet formation. Is there any clean way to solve this issue?

I thought about a 0 volume aspirate directly at the tip box, so that the transport air sucks in the droplet, but this would cost some time. I’m sure I’m not the only one facing this kind of problem with the tipbox and am curious how others solve this.

best

Dominik

1 Like

Slowing down the mix might help if there’s residual inside the tip after final dispense. You could also perform a forced airgap dispense by aspirating something like 10% of your mix volume at a zASP higher than your actual liquid (air), then zDISP over a waste trough or inside your tip isolator box to remove that remaining overage. This is sort of a band-aid rather than a solution, though.

1 Like

Reducing the mixing speed did not help, unfortunately. Adding a blowout in the tip box however, might help.

@dominik.b - I suggest that you consider using the interior lattice of the tip box as the DWP consumable you are currently using, instead of a separate plate consumable.

Not only will this save deck space and tidy loading considerations, but having the end of the tips hang idle in water while not in use will ensure that the tip rack is always ready to go, and may prevent the need for rinse mixes altogether. Additionally, this provides an advantage which may resolve your current issue, which is standard practice when using tip isolators.

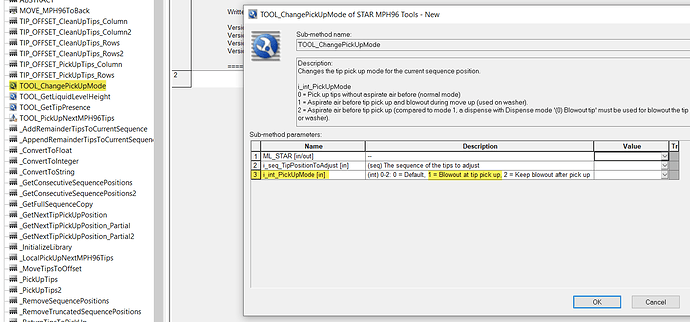

Using the MPH96 Tools library of the STAR Tools library suite, prior to tip pickup of the partially submerged tips, you can call the function ‘TOOL_ChangePickUpMode’ upon the particular sequence of tips. This will add/change a labware property of the tip rack labware, that will influence how the MPH behaves just prior to and during tip pickup from the specific rack.

If using tip pickup mode 1, as the MPH positions itself for tip pickup, dosing drive will have the plungers draw a blowout volume right before loading the tip rack, where the plungers will then force the blowout volume out while retracting in Z. This will ensure no liquid is present inside the end of the tip after retracting out of the liquid contained in the isolator (tip box lattice).

This value can be reset to default for the racks of interest if needed later in the run, but does not carry over from run to run.

-Nick

5 Likes

Wow, thanks Nick!

I’ll try this as soon as possible, however, I’d prefer to keep the additional DWP, as I’m planing to reuse the tips multiple times are different points of our workflow, and would have a strange feeling having them filled with water over a couple of weeks. Will keep you posted how this blowout works out for me

@NickHealy_Hamilton I tried it and it works perfectly, even without having liquid in the container. Thank you very much, this is now my first “real” method that’s actually working to perfection!

4 Likes

That is such a good feeling, isn’t it, @dominik.b ?? Nick is the man. Glad you’re up and running on this one!

3 Likes