Hello,

Happy holidays forum🎄,

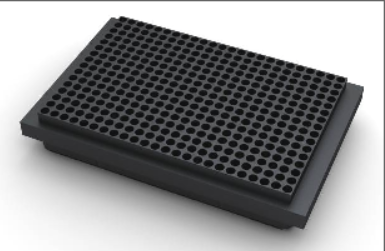

I would like to optimize my 384well serial dilution method by using two columns of 50ul tips place on a tips adaptor. I can probably achieve that with offset commands, but was wondering if they were others alternatives? Also, I need to add logic for using the 50ul tips for larger volume during the serial dilution.

Any suggestions?

1 Like

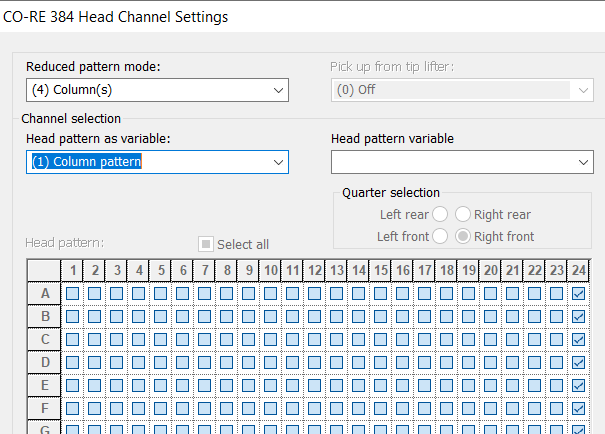

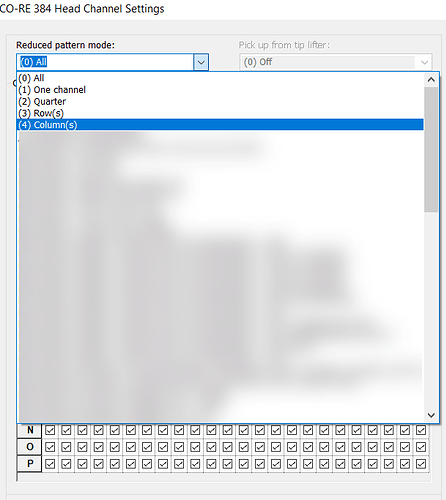

@Starrif2263 - Using a tip offset, the 384MPH can process partial racks (column/row/quadrant/single tip) of 384 format tips via channel settings configuration for reduced channel pattern processing in the tip pickup command. You can use the selectable GUI in the step to specify a hardcoded number of columns to use, or program channel patterns for dynamic processing.

There are not alternatives with the 384 MPH, as the 1mL channels cannot pick these tips up and move them around to empty wafer positions.

Regarding your other question about handling larger volumes, could you please provide more detail on your intended application, or the specific guidance you are seeking? What aspect of larger volume transfers is providing an obstacle?

Thanks.

-Nick

@Starrif2263 - Couple of follow up disclaimers here regarding shifted tip pickups using the 384 MPH.

-

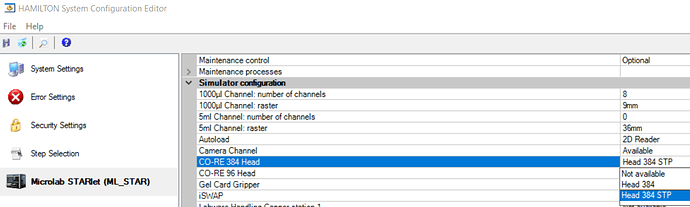

This functionality is only enabled with the STP version of the 384 MPH. However, the predecessor version has not been manufactured for several years. You likely have the STP style 384 MPH, unless your system is very old. This document provides clarification.

-

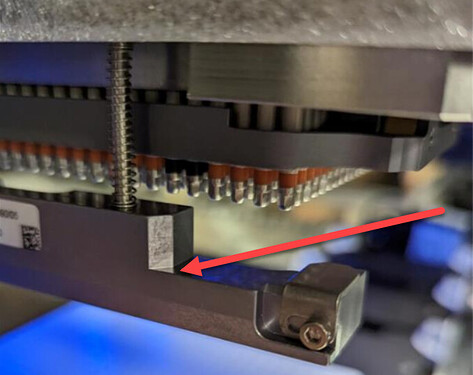

For shifted tip pickups, it is very important that the tip eject bars are disabled during tip pickup. If not these are not disabled, there can be risk of collision during pickup.

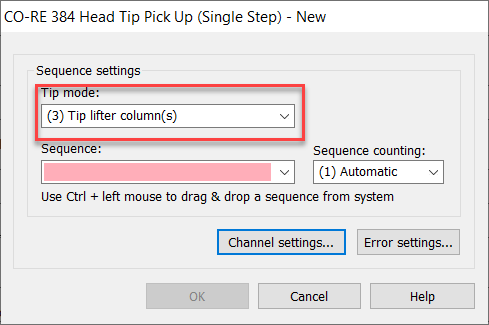

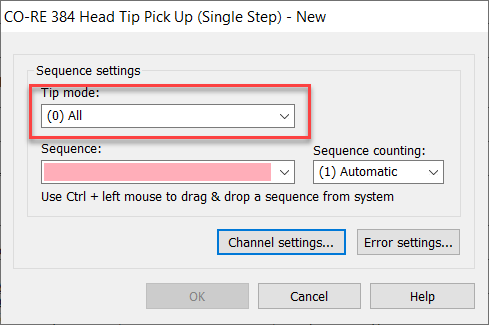

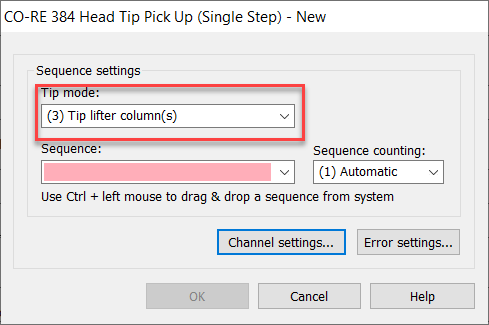

I do not currently have access to a 384MPH to test, but am seeking confirmation on how these are toggled during tip pickup. I believe they may be turned off by selecting tip mode 3 in the tip pickup step

Ill follow up when I can get confirmation, but if you wanted to test yourself in the meantime, be sure to clear your deck to prevent any possibility of collision. Test tip pickups where there is nothing and just let the command error (‘No tips picked up’) until you confirm that that the eject bars will not extend during tip pickup.

@NickHealy_Hamilton thanks for the tips. I will give that a trial.

My serial dilution volumes are dynamically calculated based on dilution factors. This means that in some case, the volume will be larger then the max tip volume. The way, i came up to handle this would be similar to how the volumes are handles with smart steps. Calculate number of loops needed for volume transfer, then transfer a

(Volume / number of loops).

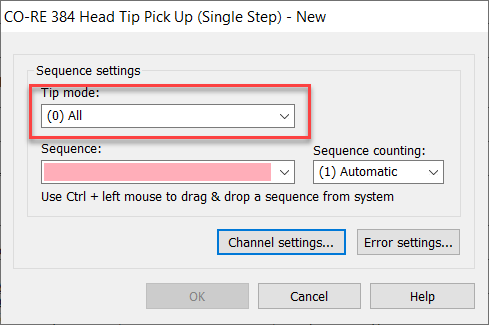

@Starrif2263 - So per my understanding, there are two ways you can prevent the tip eject/support bars from engaging during a MPH 384 tip pickup. In all cases, ensure your system configuration is set for STP, otherwise reduced channel patterns will not be available:

Disable bars during shifted pickups:

Set tip pickup mode to default (1)

Any non zero reduced pattern mode (1-4 based on use) should disable bars from engaging.

Disable bars during full rack pickups:

Set tip pickup mode to (3) and leave channel settings as default. This would likely only be useful in scenarios that pickup full racks from a tip offset, or special cases like a pin tool. When picking up full racks from NTRs, the bars are recommended.

Again, I would test these cases with an empty deck to confirm behavior and prevent possibility of collisions before using with carriers and labware.

1 Like

@Starrif2263 - Your approach regarding transfers that exceed tip capacity is valid, and how I would approach it in this scenario.

-Nick

Hi @NickHealy_Hamilton,

Just a follow up to this thread. How does the reduced tip pattern work with rocket tips? I have tried different setting, but the eject bars are always extending when i pick the tips.

Thanks,

Cheers

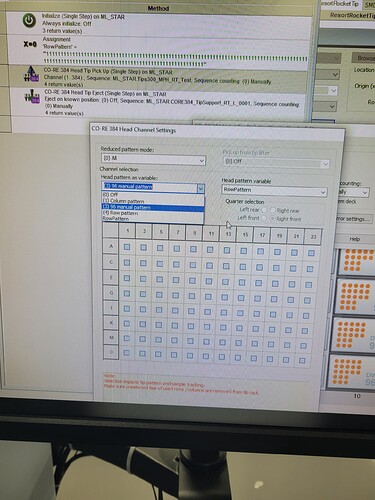

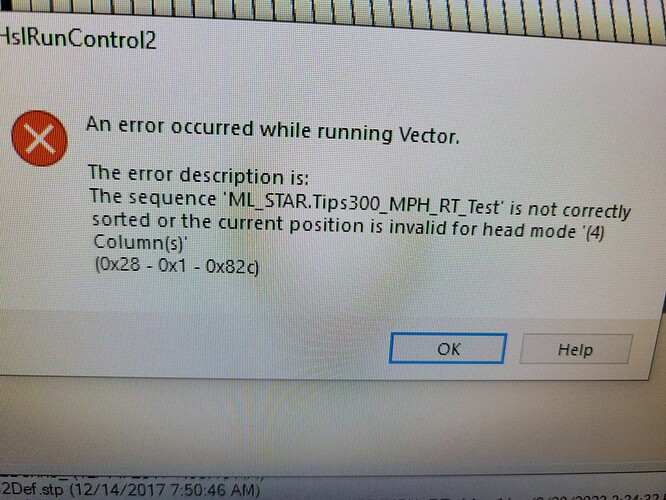

@Starrif2263 - Can you post your tip pickup settings? Any non-zero value for reduced pattern mode in the channel settings of the MPH384 tip pickup step will result in the labware centering bars not being used or extended during tip pickups.

Once you have specified your reduced pattern mode, you can either use the head pattern GUI to specify a probe pattern by selecting columns/rows/quadrants or corner probe, or opt to pass in a head pattern variable to specify the desired probes to use for the tip pickup.

-Nick

1 Like

Thanks Nick,

Your suggestion was dead on. I was using the wrong settings.

After correcting using your suggestion, i struggled with sorting the sequence for head mode, but manage to get the tip pick up to work.

What is the proper way to sort the sequence when using the reduced pattern? It was a trials an errors for me.

Thanks again Nick.

@Starrif2263 - No problem, glad to be able to help.

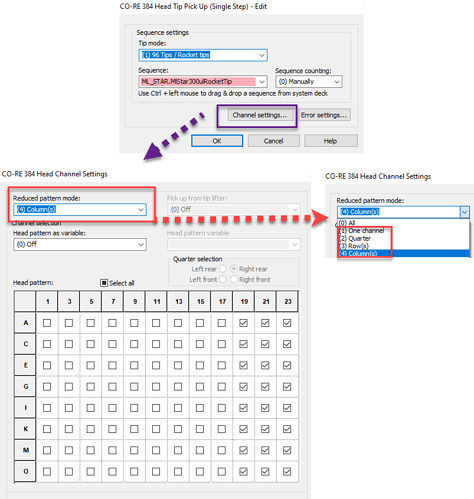

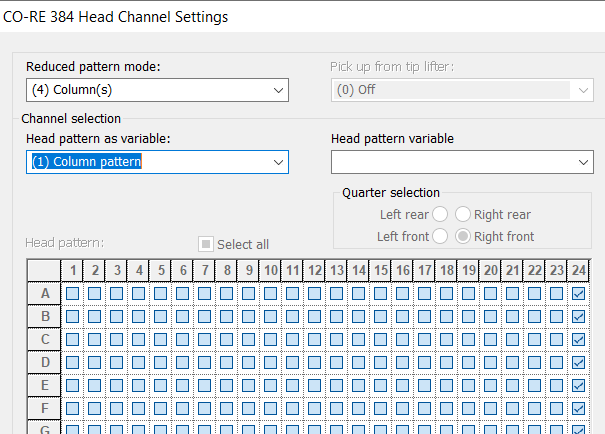

Regarding sequence sorting and probe pattern selection, it ultimately comes down to preference depending on whether or not you want the MPH384 to pick up columns of tips using the RHS or LHS of the MPH.

Lets break it down.

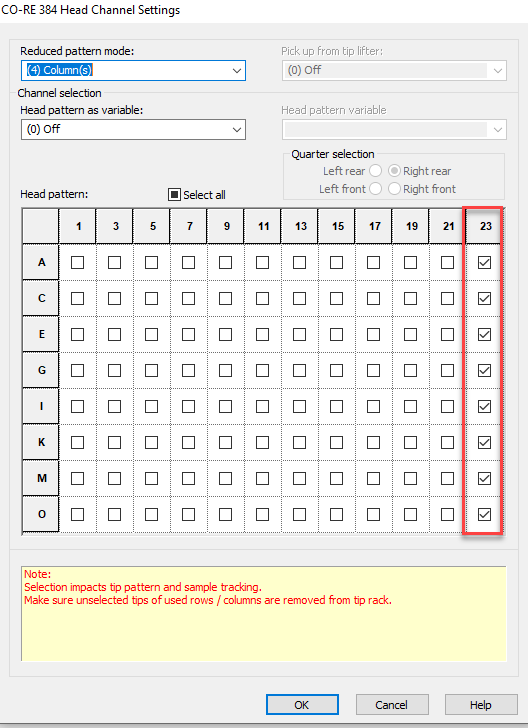

In the image below, I have specified that I want to use the RHS (right most-probes) to pick up a single column of rocket tips. In order to use the right side of the MPH, it needs to approach the rack of tips at the left of the rack (wherever there are remaining tips/sequence positions).

By default, tip sequences are sorted y descending and x ascending, meaning positions by columns are sorted left to right. In this case, because I am using the RHS of the MPH to pick up tips from the left most side of the tip rack (as that is how the tip positions are sorted positionally) the unused probes of the MPH are clear left of the rack in unused airspace.

Had I specified to use the other side (LHS) of the MPH and to pick up a single column of tips, if there were more than one column of tips left in the rack (using default sorting of tip columns left to right), then there would be MPH probes that would be inserted into additional columns of tips to the right, which would not be intended to be loaded.

Before the step is executed, VENUS is running logical checks to make sure this isn’t going to be the case. If it is, you will be met with the error you encountered earlier today, as it is not possible for the MPH to accomplish that type of reduced pickup when approaching the tip rack from that direction (without picking up extra unwanted tips). In this case, you would need to sort the sequence of rocket tips by x descending - columns right to left.

If you have no preference, it is simpler to leave the tip sequence sorted as default and use the RHS of the MPH for column pickups, by specifying the head pattern using the appropriate number of right-most probe columns.

-Nick

1 Like

Thanks @NickHealy_Hamilton,

Great explanation, I was not aware of the logic by venus.

Cheers,

@Starrif2263

2 Likes